Custom Designed & Manufactured Nitrile Sheave Seal for the Oil & Gas Industry

Crown block sheaves are located at the top of a drilling rig, making repairs extremely difficult. One of the largest drilling operators in the world contacted our company to address the high failure rate and challenges associated with the application.

After extensive on-site analysis, it was discovered that the major cause of leakage was improper installation. Seals were being removed with screwdrivers and installed with hammers, damaging both the sheave and seal and causing premature leakage.

Clark engineers set out to solve the problem by experimenting with forward-thinking sealing principles not currently available. They focused on seal installation & retention forces, studying insertion forces of both lubricated and dry seals. They tested seals on the low side and high side of the allowable tolerances and calculated the installation and removal forces on different thicknesses of rubber and metal case. They further experimented with different seal diameters, rubber thicknesses and interference between the rubber OD and sheave bore. Last, they formulated custom elastomers that would better reduce strain and retention force.

The finished design not only represented a perfect sealing solution for the industry but also one of the most significant advancements in seal design technology in 20 years - the world's first hand install seal. Today, Clark Sheave Seals are used by more than 95% of sheave applications world-wide and are currently being tested in other industries with difficult installation parameters.

(click on thumbnail to enlarge)

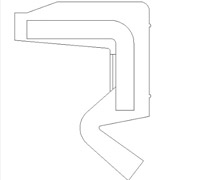

Sheave Seal

Sheave Seal Drawing

Custom Designed & Manufactured Seal Specifications

- Product Name

- Sheave Seal

- Product Description

- Patented Hand-Install Sheave Seal

- Capabilities Applied/Processes

-

- Problem Seal Analysis

Application Engineering - Custom AutoCAD Seal Design

Precision Manufacturing

- Problem Seal Analysis

- Manufacturing Equipment Used

- Tapered Roller Bearing Sheave

- Overall Dimensions of the Seal

- Ö6.503 x 0.437 (OD x H)

- Tightest Tolerances Met

- RMA Standards, .001"

- Material Used

- ELASTOMER: NITRILE

METAL CASE: Carbon Steel

- Features

- Patented Hand-Install Design

- Benefits

- Eliminates improper installation and greatly reduces replacement time

- In process testing performed

- Field Testing

- Estimated Part Weight

- 0.236 lbs

- Standards Met

- Nitrile resp. ASTM D2000 M2BG 714

Metal case material spec.: SAE 1008

- Industry for Use

- Oil & Gas

- Delivery Location

- United States and around the world

Print This Page

Print This Page